In-mold Electronics (IMD / IME / FIM)

What is In-mold electronics, In-mold decorating, or Film Insert Molding?

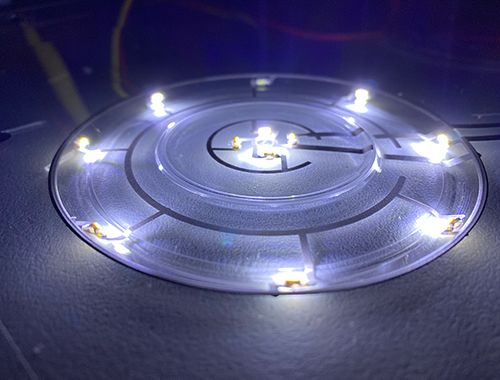

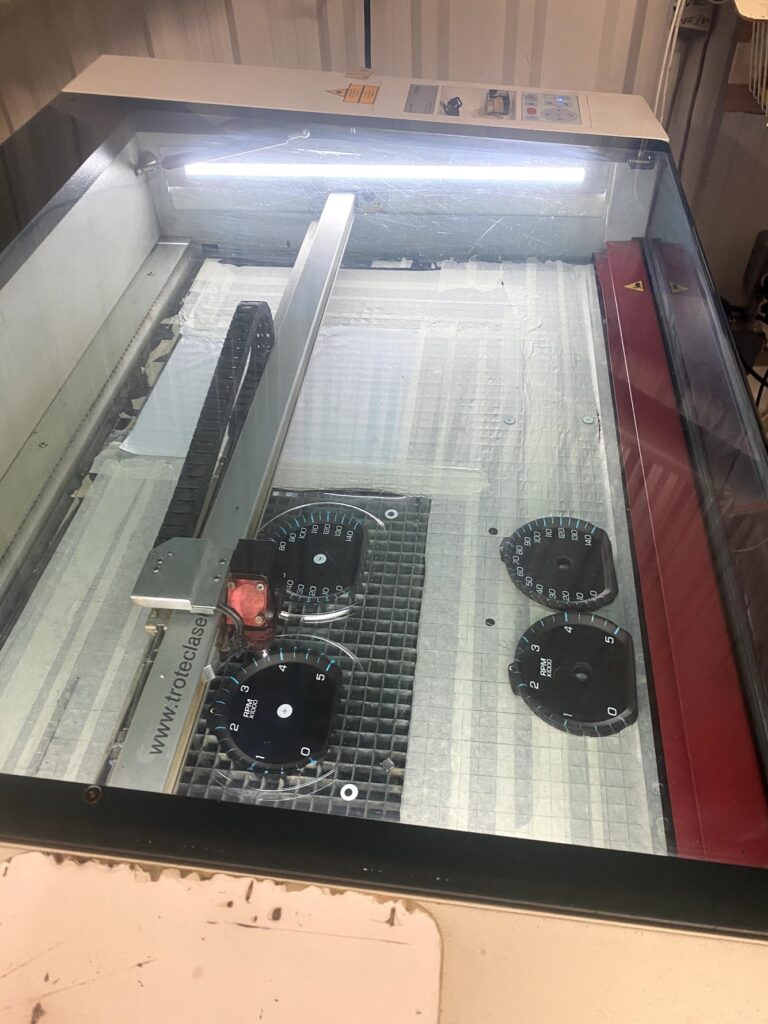

The process of Thin Film forming, is an integrated combination of technologies. Starting with our high resolution screen presses we can print graphics or conductive inks (Silver, copper, nickel, carbon). For functional products we can add capacitive keys and multilayer routing. Products can then proceed to our high speed pick and place line for LEDs, resistors, capacitors, and other basic electrical components. Graphic products can proceed without these processes. We then proceed to our Niebling SAMK650 high pressure forming machine. The only one in North America, and one of the only Niebling presses with contract availability.

In mold electronics is the future of integrated functional product design.

What are the advantages of In-Mold Electronics?

- Much lighter product – expert sources show an in-mold electronics product can be up to 70% lighter than a traditional build

- More durable – with the electronics encapsulated in plastic moisture and harsh environments do not affect the end product.

- Less cost – few parts and few steps reduce the ultimate manufacturing cost. What you receive from True North is a plug and play In mold electronics device with capacitive keys, leds, resistors, already in place. The controller PCB becomes very small and simple.

- More freedom of design – with in-mold electronics your capactive keys can take any shape or size, they can be on the side walls of features, shaped like domes, be back lit, and be integrated into the graphics.

- More functional – by bringing the capacitive pads close to the surface with no air gaps, in mold electronics can give you a stronger clearer signal than ever before.

Why Niebling?

Niebling offers a unique advantage for in-mold electronics using hot air for no mechanical contact on the first surface. This allows matte textures to stay matte. It also allows slight negative draft features to be incorporated. This off contact process is also what allows us to handle electronic components without crushing them as we inject up to 90 bars of heated air pressure.

With a forming area of up to 720mm X 400mm (28 x 16 inches) and up to 53mm depth of draw, we can handle large parts!

Why choose True North?

True North has 37 years experience in the screen printing industry. Specializing in screen printed electronics for the past 30 years.

True North has managed successful IMD / FIM programs for major companies such as Nokia, Blackberry and Hewlett-packard.

As a fully integrated company we do not need to subcontract out any part of the process, from design, printing, forming, trimming (mechanical or laser) and finishing we can do it all.

We work with great partners such as MacDermid Autotype, Henkel advance materials and electronics, Kiwo adhesives, Sabic, 3M adhesives, just to name a few. We are proud to integrate with our entire supply chains engineers to give you the best solution possible.

I’m interested, whats next?

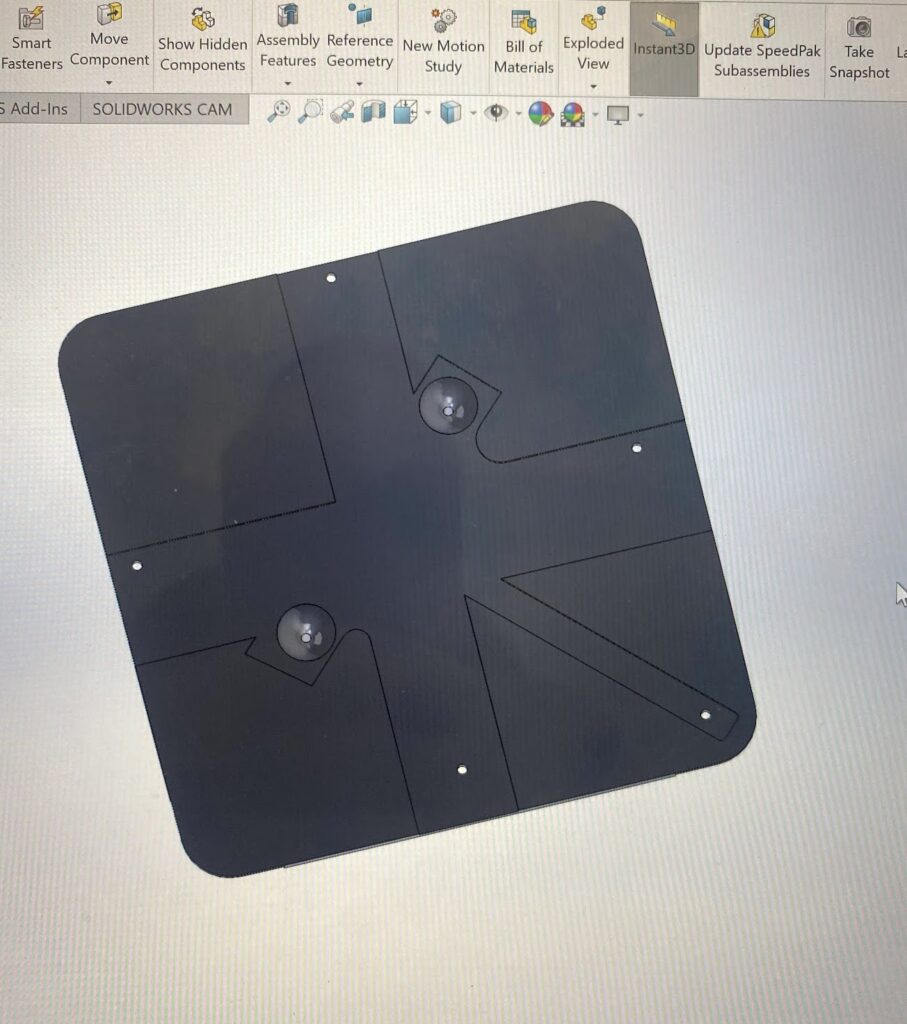

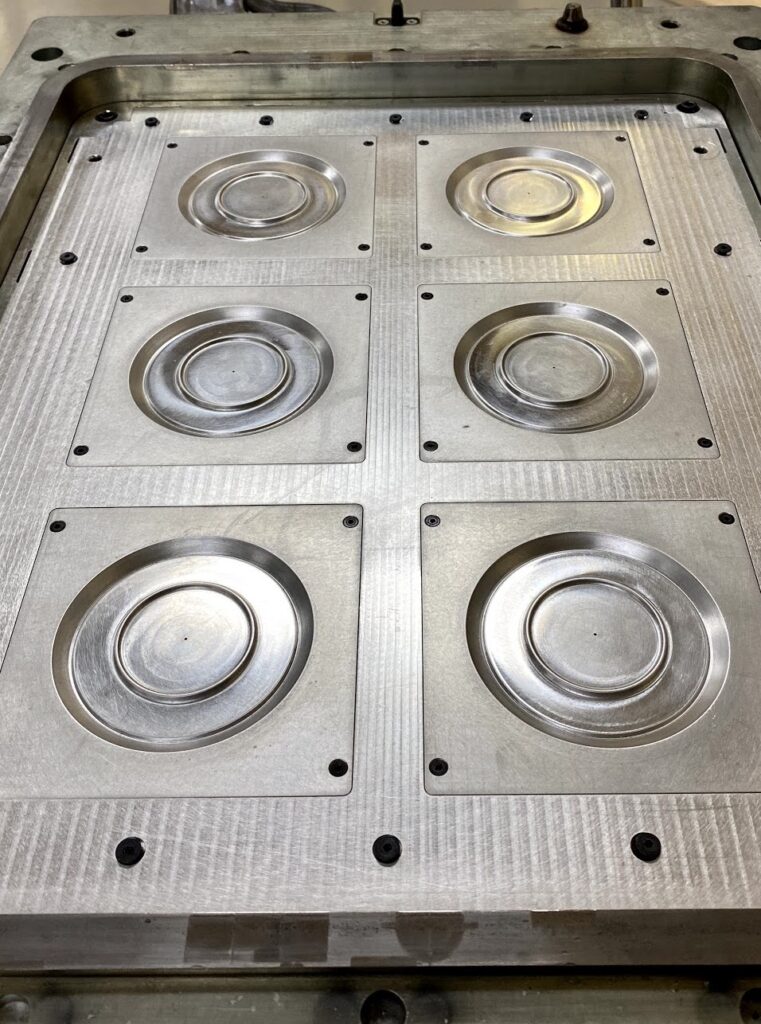

Contact our amazing customer service team and we can get started. Our engineers will work through product design or manufacturing readiness in solidworks with you. We can then proceed to 3d printed tooling or too milled aluminum tooling. Our concept for tooling gets you access at a fraction of the price of other options.

Once ready we can help with product validation, graphic changes, custom logos, or whatever else it takes to make your product a great success!

Need a membrane Switch?

Do you need an interactive membrane switch for your product? Interfaces are our bread and butter. We can make your product functional and beautiful.

Overlays and Labels

Learn more about our overlay, label, and nameplate offerings. We can manage the simple to the complex by combining our technologies.